Rotary Tablet Press for Continuous Tablet Production

Introduction to Rotary Tablet Press Technology

The rotary tablet press represents one of the most significant advancements in pharmaceutical manufacturing technology, enabling continuous tablet production with high efficiency and precision. This sophisticated equipment has revolutionized tablet manufacturing by offering superior speed, consistency, and automation compared to traditional single-station presses.

At its core, a rotary tablet press operates on the principle of continuous compression through multiple tooling stations arranged around a rotating turret. As the turret rotates, each station sequentially performs the filling, compression, and ejection functions that transform powder formulations into precisely formed tablets. The continuous nature of this process allows for uninterrupted production at rates that can exceed one million tablets per hour in high-capacity models.

Modern rotary tablet presses incorporate advanced control systems that monitor and adjust critical parameters in real-time, ensuring consistent tablet quality throughout extended production runs. These machines have become indispensable in pharmaceutical manufacturing, nutraceutical production, and other industries requiring high-volume tablet production with strict quality standards.

Working Principle of Rotary Tablet Presses

The operational mechanism of a rotary tablet press involves several precisely coordinated components working in harmony to produce tablets continuously:

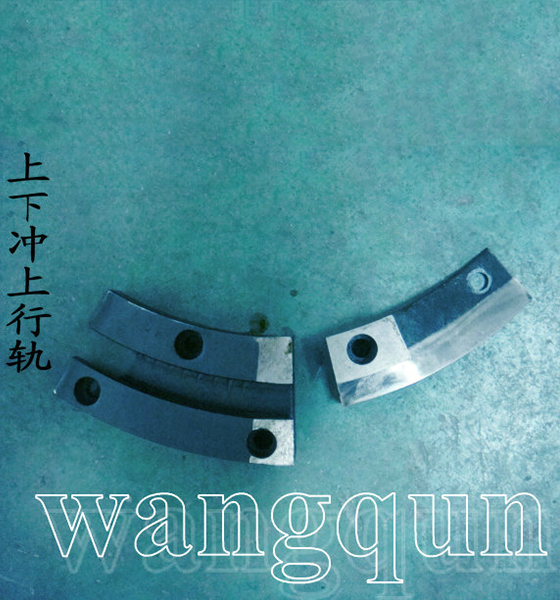

1. Turret Assembly: The heart of the machine, this rotating component holds multiple sets of upper and lower punches along with corresponding dies arranged in a circular pattern. The number of stations varies from as few as 16 to over 75 in large production machines.

2. Feeding System: Powder or granulated material is fed into the dies through a feed frame that ensures consistent filling as the turret rotates. Modern systems may include multiple feed frames for layered tablets or special designs for challenging formulations.

3. Compression Rollers: Stationary compression rollers interact with the rotating punches to apply the necessary force to form tablets. Pre-compression rollers initially consolidate the powder before the main compression rollers apply the final tablet-forming pressure.

4. Ejection Mechanism: After compression, the lower punch rises to eject the finished tablet from the die, while take-off blades guide the tablet away from the turret to the collection system.

5. Control Systems: Advanced microprocessor controls manage turret speed, compression force, fill depth, and other critical parameters while monitoring production data and machine performance.

The continuous rotation of the turret allows each station to simultaneously perform different stages of the tablet production cycle, creating a seamless manufacturing process with minimal downtime between batches.

Key Components and Their Functions

Understanding the major components of a rotary tablet press provides insight into its operation and capabilities:

1. Turret: The rotating platform that holds the tooling sets (punches and dies). Precision machining ensures perfect alignment of all components during high-speed operation.

2. Punches and Dies: Tooling sets consisting of upper punches, lower punches, and dies that determine tablet size, shape, and embossing. These are manufactured from high-grade steel to withstand repeated compression forces.

3. Feed Frame: Distributes the powder formulation evenly into the dies as they pass beneath it. Some designs incorporate agitators or paddles to ensure consistent flow of material.

4. Compression Rollers: Apply the force needed to form tablets. Main compression rollers typically provide forces ranging from 2 kN to 100 kN depending on machine size and application.

5. Weight Control System: Adjusts the fill depth of the lower punches to maintain consistent tablet weight. Modern systems use automatic feedback loops for continuous adjustment.

6. Ejection Cam: Guides the lower punches upward to eject finished tablets from the dies after compression.

7. Dust Extraction System: Removes excess powder and maintains clean operation, particularly important for potent compounds or sensitive formulations.

8. Instrumentation and Sensors: Monitor compression force, tablet thickness, turret speed, and other parameters to ensure quality and identify potential issues.

9. Safety Systems: Include guards, interlocks, and emergency stops to protect operators during machine operation and maintenance.

Advantages of Rotary Tablet Presses in Continuous Production

Rotary tablet presses offer numerous benefits that make them ideal for continuous tablet manufacturing:

1. High Production Capacity: Capable of producing hundreds to thousands of tablets per minute, far exceeding the output of single-station presses.

2. Consistent Quality: The continuous process and multiple compression stations ensure uniform tablet characteristics throughout production runs.

3. Precision Control: Advanced systems maintain exact control over weight, hardness, thickness, and other critical quality attributes.

4. Flexibility: Quick changeover between different tablet shapes and sizes using interchangeable tooling sets.

5. Automation Compatibility: Easily integrated with automated material handling, coating, and packaging systems for complete production lines.

6. Reduced Labor Requirements: Continuous operation with automated controls minimizes the need for operator intervention.

7. Improved Material Utilization: Precise filling and compression mechanisms reduce waste compared to batch processes.

8. Data Collection: Built-in monitoring systems collect production data for quality control and process optimization.

9. Scalability: Available in various sizes to accommodate different production volumes from development to full-scale manufacturing.

10. Process Validation: Designed to meet stringent regulatory requirements for pharmaceutical production with comprehensive documentation capabilities.

Types of Rotary Tablet Presses

Various configurations of rotary tablet presses exist to meet different production needs:

1. Single-Sided Presses: Feature one compression station per tooling set, suitable for standard tablet production.

2. Double-Sided Presses: Incorporate two compression stations per tooling set for higher output or special tablet formulations requiring multiple compression stages.

3. Multi-Layer Presses: Designed to produce layered tablets with different materials in each layer, using multiple feed systems.

4. Bi-Layer Tablet Presses: Specialized for producing tablets with two distinct layers, often for controlled release applications.

5. Tri-Layer Presses: Advanced systems capable of producing three-layer tablets for complex drug delivery systems.

6. Coated Tablet Presses: Integrated systems that apply coatings immediately after compression in a continuous process.

7. Miniature Tablet Presses: Smaller machines designed for producing very small tablets or for development work.

8. GMP-Grade Pharmaceutical Presses: Designed specifically to meet stringent pharmaceutical manufacturing requirements.

9. Nutraceutical Presses: Optimized for dietary supplement production with features tailored to common supplement formulations.

10. Industrial Presses: Heavy-duty machines for non-pharmaceutical applications such as detergent tablets or chemical products.

Critical Process Parameters in Rotary Tablet Compression

Successful continuous tablet production requires careful control of several key parameters:

1. Compression Force: Typically ranging from 5 kN to 40 kN for most pharmaceutical tablets, adjusted based on formulation characteristics.

2. Turret Speed: Measured in rotations per minute (RPM), directly affecting production rate. Must be balanced with other parameters to maintain quality.

3. Fill Depth: Determines the amount of material in each die, controlling tablet weight. Adjusted through the lower punch penetration depth.

4. Pre-Compression Force: Initial compression force that prepares the powder for final compression, particularly important for certain formulations.

5. Dwell Time: Duration that the powder is under maximum compression force, affected by punch head geometry and turret speed.

6. Feeding System Parameters: Including feed frame speed, paddle agitation, and powder level in the hopper.

7. Tooling Temperature: Managed through cooling systems to prevent sticking or picking issues during prolonged operation.

8. Environmental Conditions: Controlled humidity and temperature in the compression area to maintain powder flow and compression characteristics.

9. Ejection Force: Monitored to detect potential sticking or tooling wear issues.

10. Take-off Blade Position: Adjusted to ensure clean tablet ejection without damage to tablets or tooling.

Quality Control in Continuous Tablet Production

Maintaining consistent quality during continuous tablet production involves multiple control measures:

1. In-Process Checks: Regular sampling and testing of tablets for weight, hardness, thickness, friability, and disintegration.

2. Automated Weight Control: Continuous monitoring and adjustment of tablet weight through feedback systems.

3. Force Monitoring: Real-time measurement of compression forces at each station to detect variations.

4. Thickness Measurement: Laser or contact sensors verify tablet thickness consistency.

5. Visual Inspection Systems: Camera-based systems detect visual defects such as cracks, chips, or discoloration.

6. Dust Extraction Control: Maintains proper powder containment and prevents cross-contamination.

7. Material Tracking: Ensures proper material flow and prevents segregation during extended runs.

8. Tooling Inspection: Regular checks for wear or damage that could affect tablet quality.

9. Environmental Monitoring: Controls temperature and humidity in the compression zone.

10. Data Recording: Comprehensive logging of all process parameters for quality assurance and regulatory compliance.

Challenges in Continuous Tablet Production and Solutions

While rotary tablet presses offer significant advantages, they also present unique challenges:

1. Material Flow Issues: Poorly flowing powders can cause inconsistent filling. Solutions include:

- Optimizing powder granulation

- Using feed frames with agitators

- Incorporating force feeders for difficult materials

2. Sticking and Picking: Formulation adherence to tooling surfaces. Addressed by:

- Appropriate tooling coatings

- Optimized punch tip designs

- Formulation adjustments with lubricants

3. Capping and Lamination: Tablet layer separation. Prevented by:

- Adjusting compression force profile

- Optimizing pre-compression settings

- Modifying granulation properties

4. Weight Variation: Inconsistent tablet mass. Controlled through:

- Automated weight control systems

- Improved powder flow characteristics

- Regular tooling maintenance

5. Heat Generation: Friction during continuous operation. Managed with:

- Turret cooling systems

- Controlled compression speeds

- Intermittent operation cycles for sensitive materials

6. Tooling Wear: Extended use leads to dimensional changes. Mitigated by:

- Regular inspection schedules

- Using high-quality tooling materials

- Implementing predictive maintenance

7. Cross-Contamination: Between product changes. Prevented through:

- Comprehensive cleaning procedures

- Dedicated tooling sets

- Proper changeover protocols

8. Regulatory Compliance: Meeting stringent requirements. Ensured by:

- Complete process documentation

- Validation protocols

- Audit trails for all critical parameters

Maintenance Requirements for Rotary Tablet Presses

Proper maintenance is essential for reliable continuous operation:

1. Preventive Maintenance Schedule: Regular inspections and servicing of all components according to manufacturer recommendations.

2. Lubrication Program: Proper lubrication of all moving parts using approved lubricants that won't contaminate products.

3. Tooling Maintenance: Regular inspection, cleaning, and replacement of punches and dies to maintain tablet quality.

4. Calibration Checks: Periodic verification of all instrumentation and control systems.

5. Wear Part Replacement: Timely replacement of components subject to normal wear such as cam tracks, rollers, and seals.

6. Cleaning Procedures: Thorough cleaning between product changes following validated protocols.

7. Software Updates: Keeping control system software current with the latest versions and patches.

8. Safety System Verification: Regular testing of all safety interlocks and emergency stop functions.

9. Alignment Checks: Ensuring proper alignment of all rotating components to prevent vibration and premature wear.

10. Record Keeping: Comprehensive documentation of all maintenance activities for regulatory compliance.

Future Trends in Rotary Tablet Press Technology

The evolution of rotary tablet press technology continues with several emerging trends:

1. Increased Automation: Further integration with robotic material handling and packaging systems for complete lights-out manufacturing.

2. Advanced Process Analytics: Implementation of machine learning algorithms for real-time process optimization and predictive maintenance.

3. Enhanced Flexibility: Quick-change systems that reduce changeover time between different products and formats.

4. Continuous Manufacturing Integration: Tighter coupling with upstream and downstream processes for fully continuous production lines.

5. Improved Material Handling: Advanced feeding systems capable of handling increasingly challenging powder formulations.

6. Sustainable Design: Energy-efficient operation and reduced material waste through precision control systems.

7. Compact Footprint: Development of high-capacity machines with smaller footprints for space-constrained facilities.

8. Remote Monitoring: Cloud-based systems for remote operation, troubleshooting, and performance monitoring.

9. Advanced Tooling Materials: New coatings and materials that extend tooling life and improve tablet quality.

10. Regulatory Technology: Built-in systems to simplify compliance with evolving global pharmaceutical regulations.

Conclusion

The rotary tablet press has become the cornerstone of modern tablet manufacturing, offering unparalleled efficiency, consistency, and control in continuous production environments. Its ability to produce high-quality tablets at remarkable speeds while maintaining strict quality standards has made it indispensable in pharmaceutical and nutraceutical manufacturing.

As technology advances, rotary tablet presses continue to evolve, incorporating smarter controls, greater flexibility, and enhanced integration with other production systems. These improvements ensure that rotary tablet presses will remain at the forefront of tablet manufacturing technology, capable of meeting the growing demands for pharmaceutical products worldwide while maintaining the highest quality standards.

Understanding the principles, components, and operation of rotary tablet presses is essential for optimizing continuous tablet production processes. By carefully controlling critical parameters and implementing robust maintenance and quality control programs, manufacturers can leverage the full potential of these sophisticated machines to produce tablets that meet exacting specifications consistently and efficiently.

Téléphone

Téléphone

Commentaire

(0)